We focus on R&D, production and sales of automotive electronic precision components, precision connectors and other components.

-

Automotive Electronics

After years of accumulation and development, Vico Precision has formed key product systems of power system components, chassis system components, NEV components, automotive connectors and components. Our products, such as components for fuel injectors, high-pressure sensors, automatic transmission solenoid valve coils and exhaust treatment units, have occupied high shares and are in a leading position in the market.

-

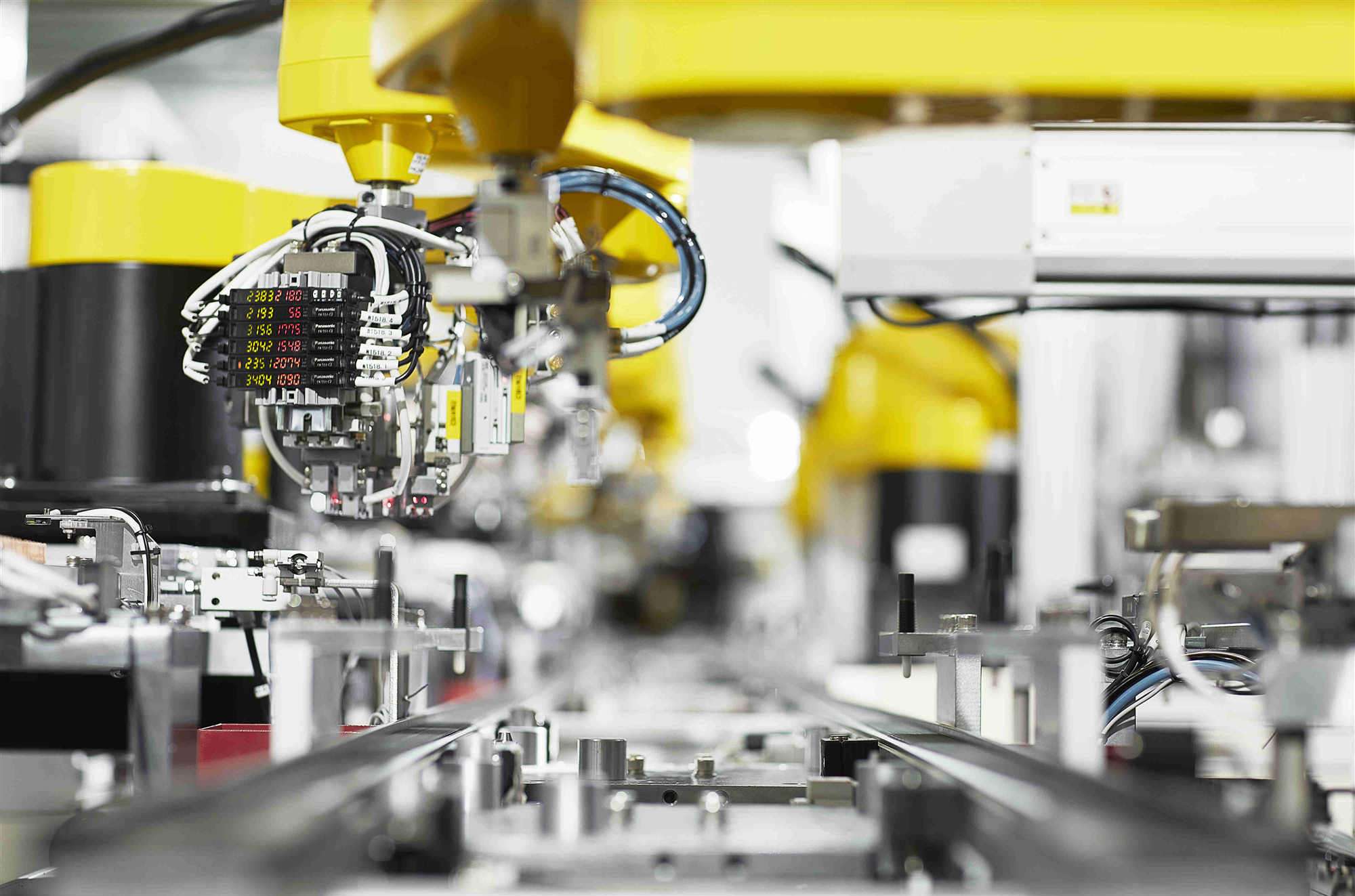

Precision Connectors

Main products are electrical connector in communication, consumer electronics, industry and other sectors. Our product are widely used in communication base stations, mobile phones, household appliances, industrial robots, etc.

-

30000 m 2Floor area

-

47000 m 2Building area

-

1000+Number of employees

-

Mission

Create values for the society

-

Vision

Become an excellent intelligent manufacturer of key automotive components

-

Six core values

Customer firstTeamwork

Innovation and changeEfficient execution

Good engagementSustainable learning and development -

Quality Policy

Provide customers with defect-free products

History

-

2023

-

VICO has successfully landed on the Growth Enterprise Board of the Shenzhen Stock Exchange, stock code: 301499

-

Launching of project management system

-

-

2022

-

Awarded the title of a national SRDI "little giant" enterprise

-

The individualized mold customization workshop has been recognized as the "Digital Workshop in Minhang District, Shanghai"

-

-

2021

-

Formally renamed as Shanghai Vico Precision Mold & Plastics Co., Ltd.

-

Awarded the title of "Foreign-funded R&D Center in Shanghai"

-

-

2019

-

Successfully setup of a management system integrating industrialization and industrialization

-

-

2018

-

Awarded the title of "SRDI (Specialized, Refined, Differential and Innovative) Enterprise" and "Shanghai Municipal Enterprise Technology Center" in Shanghai

-

-

2016

-

Launching of intelligent manufacturing system for molds

-

-

2015

-

Establishment of an automated production line R&D, manufacturing and integration team

-

Awarded the title of "Shanghai Hi-tech Enterprise"

-

-

2013

-

Successful development of the first FI oil injection system EV14 coil project, and overcome of core technology

-

Engagement in NEV electronic products

-

-

2012

-

Establishment of a precision testing room and physics lab

-

-

2011

-

Expand of new precision punching and winding processes

-

-

2008

-

Completed self-design and manufacturing of precision dual-color products

-

Awarded the title of "Technologically Advanced Little Giant"

-

-

2007

-

Mass production of domestic plastic parts for inlet and outlet oil plates, instead of aluminum alloy parts

-

Awarded the title of "Shanghai Star Enterprise Funded by Overseas Chinese"

-

-

2006

-

Expand of precision stamping mold design and product self-development

-

-

2002

-

Expand of product assembly process

-

-

1999

-

Establishment of Shanghai Vico Precision Molding Co., Ltd.

-

-

2023

-

2022

-

2021

-

2019

-

2018

-

2016

-

2015

-

2013

-

2012

-

2011

-

2008

-

2007

-

2006

-

2002

-

1999

Social responsibility

-

01Strive to improve education in impoverished areas

01Strive to improve education in impoverished areasWe invested to build hope primary schools in Yunnan and arrange teachers to Shanghai for training every year to improve their teaching quality.

-

02Devote to cultivating professional talents in the industry

02Devote to cultivating professional talents in the industryWe developed tailored training plans for different groups and established university-enterprise cooperation with East China University of Science and Technology.

-

03Strive to lead intelligent and high-tech manufacturing

03Strive to lead intelligent and high-tech manufacturingWe owned titles such as "High-tech Enterprise", "SRDI (Specialized, Refined, Differential and Innovative) Enterprise" and "Shanghai Municipal Enterprise Technology Center".

-

04Energetically create green and environmentally friendly new products

04Energetically create green and environmentally friendly new productsIn response to national call for energy conservation, emission reduction and green environmental protection, we have been fully developing and building NEV products.

Honors and qualifications

-

2023-Bosch HUAYU Steering Systems Outstanding Technical innovation & Breakthrough Supplier

2023-Bosch HUAYU Steering Systems Outstanding Technical innovation & Breakthrough Supplier -

2023-ZHUZHOU CRRC Joint Innovation Award

2023-ZHUZHOU CRRC Joint Innovation Award -

2022 - BOSCH Best Supplier in Asia Pacific Region

2022 - BOSCH Best Supplier in Asia Pacific Region -

2022 - SCHAEFFLER Best Technology Cost Reduction Award

2022 - SCHAEFFLER Best Technology Cost Reduction Award -

2021 - BorgWarner Outstanding Quality Award

2021 - BorgWarner Outstanding Quality Award -

2021 - UAES 25 th Anniversary Outstanding Contribution Award

2021 - UAES 25 th Anniversary Outstanding Contribution Award -

2020 - UAES Outstanding Quality Performance Award

2020 - UAES Outstanding Quality Performance Award -

2019 - BOSCH Global Best Supplier

2019 - BOSCH Global Best Supplier -

2018 - Amphenol TCS Best Quality Award

2018 - Amphenol TCS Best Quality Award -

2015 - IRISO QCC Excellence Award

2015 - IRISO QCC Excellence Award -

2010 - BOSCH Excellent Supplier in Asia Pacific Region

2010 - BOSCH Excellent Supplier in Asia Pacific Region -

2009 - UAES Comprehensive Performance Excellence Award

2009 - UAES Comprehensive Performance Excellence Award -

2006 - AMP-TYCO Annual Quality Award

2006 - AMP-TYCO Annual Quality Award -

Practice Base in East China University of Science and Technology

Practice Base in East China University of Science and Technology -

ISO9001 System Certificate

ISO9001 System Certificate -

IATF16949 System Certificate

IATF16949 System Certificate